Having finished all the models, takeoff, and documents required; I feel comfortable enough to turn it in. It has been a long semester, but well worth the effort, and I would do it again in a heartbeat.

While the basis of the thesis was enjoyable, the true potential of it really came about in the additional work. Looking into all of the additional software and programs that can be used to manipulate the model show the extent that BIM could have.

Final Presentations are next week in which I will try to throw something extra in for more of a visual aid. Even so, I am content with the amount I have put in and the work I have achieved thus far.

A day by day blog of activity in a BIM thesis for Auburn University's Fall 2010 term.

Friday, November 19, 2010

Sunday, November 7, 2010

Website and Finishes

Using Wix.com I found a very fast and professional Flash hosting website to make an official "Site" for my Thesis. I'll link all documents and additional work to that page and try to update it until December. You can check it out here.

Most of the misc documents progressed rather quickly. This week will mostly pertain to creating video walkthroughs, modeling the complete MEP of my building, and closing out most of the work to be graded. Then comes additional software/tech to play with

Most of the misc documents progressed rather quickly. This week will mostly pertain to creating video walkthroughs, modeling the complete MEP of my building, and closing out most of the work to be graded. Then comes additional software/tech to play with

Monday, November 1, 2010

CPM & Misc. Docs

After QTO and Pricing was finished out we had to tackle a Project Schedule. With so many items to place, I tried to keep it at a vague consistency. In addition to creating a schedule, we were required to cost-load each item. This led to the creation of the CPM.

It took at least a good few days to gather everything together and establish exactly what we were suppose to do. After much deliberation and looking back at previous class notes, we were able to finally understand how it worked.

Once we had an understanding, we proceeded with the schedule of values and pay request application. Luckily, the SOV number matched up perfectly with my CPM numbers, showing I evenly spread everything to the cent. With those knocked out, our next big project to tackle will be the project phasing of the model in Navisworks. I anticipate quite the struggle with that item.

We have 11 and a half days or so before Thesis is due. This should be plenty of time to knock out a rough MEP scope, Time Log of Work on the Thesis, Safety Plan, and Structural Assessment. Our plan is to knock out all of this by Friday, giving plenty of time to organize, provide additional work, and close everything out.

It took at least a good few days to gather everything together and establish exactly what we were suppose to do. After much deliberation and looking back at previous class notes, we were able to finally understand how it worked.

Once we had an understanding, we proceeded with the schedule of values and pay request application. Luckily, the SOV number matched up perfectly with my CPM numbers, showing I evenly spread everything to the cent. With those knocked out, our next big project to tackle will be the project phasing of the model in Navisworks. I anticipate quite the struggle with that item.

We have 11 and a half days or so before Thesis is due. This should be plenty of time to knock out a rough MEP scope, Time Log of Work on the Thesis, Safety Plan, and Structural Assessment. Our plan is to knock out all of this by Friday, giving plenty of time to organize, provide additional work, and close everything out.

Tuesday, October 26, 2010

Closing out QTO/Pricing

QTO proved useful in organzing quantites, making some sections relatively simple to takeoff. Pricing took the longest, as we still had to use the traditional Means book method of looking up labor/mat/equip and applying burden. All that is left is throwing in the recap sheet.

As the due date approaches I took a glance at the Table of Contents and realized there is still a few more items of note to get through. Site Safety plan, phasing plan, and the structural assessment seem like they may take longer than I expect.

I have been able to devise an organizational method for the material though, using a single spreadsheet to navigate to each item on the list with the click of a button. I've already applied this method to my QTO/Pricing, and figure it would work just as well for a general project table of contents.

We still have about 2 and half weeks to finish up any work we have left, which should allow us to finish on schedule.

As the due date approaches I took a glance at the Table of Contents and realized there is still a few more items of note to get through. Site Safety plan, phasing plan, and the structural assessment seem like they may take longer than I expect.

I have been able to devise an organizational method for the material though, using a single spreadsheet to navigate to each item on the list with the click of a button. I've already applied this method to my QTO/Pricing, and figure it would work just as well for a general project table of contents.

We still have about 2 and half weeks to finish up any work we have left, which should allow us to finish on schedule.

Monday, October 18, 2010

T/O & Pricing

Autdoesk QTO, while useful for organization and extracting quantities easily, is not very efficient for pricing. There are so many variables with equipment and labor crews, that the traditional method of pricing is being used.

Divison 2 is basically finished, with a few minor edits still required in pricing. I am now moving on to Division 3 for QTO and a by-hand comparison. Hopefully I will be finished with QTO&Pricing by the week's end.

I went back and modeled a bit of my rebar for the structural model, to both experience the feature and use for my comparison.

Divison 2 is basically finished, with a few minor edits still required in pricing. I am now moving on to Division 3 for QTO and a by-hand comparison. Hopefully I will be finished with QTO&Pricing by the week's end.

I went back and modeled a bit of my rebar for the structural model, to both experience the feature and use for my comparison.

Monday, October 11, 2010

Div 2 - Earthworks

Stepping out of Autocad, I'm having to go into Earthworks to generate site takeoff for Divison 2. Cutting out a certain section of my site, I've concentrated on the South-East HQ building for my project. Part of the reason in choosing this is the Chiller Pad inclusion for additional work, possibly in modeling the full HVAC system chiller pump.

Tuesday, October 5, 2010

Autodesk QTO

After completion of a clash detection report and model merge in Navisworks, I am currently figuring out Autodesk QTO. It will take some time to manipulate and figure out, but it essentially allows me to drop item quantities taken from the model and put them into assigned Divisions. While not everything is included I can bring in PDFs of floor plans if I need additional linear footage items not modeled.

This will be taking a large amount of time to figure and place correctly, so I imagine I will be doing multiple extra tasks in addition to this work as the due date closes in.

This will be taking a large amount of time to figure and place correctly, so I imagine I will be doing multiple extra tasks in addition to this work as the due date closes in.

Friday, October 1, 2010

Navisworks - Clash Detection

After merging all three files together I am dancing back and forth between Revit and Navisworks to provide clash detection fixes. It can be irritating to have to go back and forth so much, but so far I have a good handful of clashes and fixes documented.

Once I finish wrapping this up, I will need to hammer out a schedule for the project and see if I can tie it to the model and continue on to project Takeoff. I've come a long way in this Thesis, but still have so much left to do.

Once I finish wrapping this up, I will need to hammer out a schedule for the project and see if I can tie it to the model and continue on to project Takeoff. I've come a long way in this Thesis, but still have so much left to do.

Wednesday, September 29, 2010

Finishing Details on Model

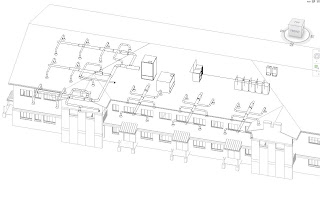

After dabbling into MEP, I feel comfortable enough to move on and finish the model in greater detail. I was able to fix the roof into one single entity, as well as detail it with a standing metal seam profile. Downspouts, though not completely accurate in design, were placed along the new gutters. The model just looks so much nicer than before.

I will continue to finish up a few last minute details, but am looking to continue into Navisworks to begin some Clash Detection and sift through them to locate truly cost-worthy items. The only other major item I would need to tend to is the Site topography and detail. Everything else seems in place enough for takeoff to begin.

I will continue to finish up a few last minute details, but am looking to continue into Navisworks to begin some Clash Detection and sift through them to locate truly cost-worthy items. The only other major item I would need to tend to is the Site topography and detail. Everything else seems in place enough for takeoff to begin.

Tuesday, September 28, 2010

Monday, September 27, 2010

MEP Troubles

MEP is proving much more of a task than I had previously assumed. It can be pretty confusing deciphering the plans on what goes where. Though this won't necessarily count toward any takeoff numbers, I still would like an accurate depiction of the supply and return air systems. My main trouble comes in identification of a few elements and ensuring I am placing the right component in the system. The first floor is basically finished, and I began work on the second floor's supply system.

After clarification I will be designing a few elements of piping for Plumbing system as well. If I can finish up the MEP systems, I can go back to the previous models and edit/alter everything for better appearance.

After clarification I will be designing a few elements of piping for Plumbing system as well. If I can finish up the MEP systems, I can go back to the previous models and edit/alter everything for better appearance.

Friday, September 24, 2010

MEP

Beginning MEP has proven more challenging than I thought it would be. Deciphering the plumbing to apply to our thesis assignment standards was questionable, and I am awaiting reply for confirmation on what I should include in the model. Until that time, I have begun the HVAC system.

The "auto link" feature, though useful in practice, is not applicable to my project as the ducts vary in size continuously. For now I am simply constucting the basic outline and mirroring elements along different axis to line up in each room. Though there are a few snags along the way, the general idea is coming along.

The "auto link" feature, though useful in practice, is not applicable to my project as the ducts vary in size continuously. For now I am simply constucting the basic outline and mirroring elements along different axis to line up in each room. Though there are a few snags along the way, the general idea is coming along.

Monday, September 20, 2010

Closing Out Architectural

Already behind schedule, I need to finish up the architectural. Stair railings were put in place, along with ceiling grids, and other little items like room labeling.

My main trouble was getting the EIFS/roof for the stairs working correctly. I had to go back to my structural to check a few slopes and adjust a few beams to make it work. It's still not as perfect as I need it to be, and I'm sure I'll be back in it to adjust the edges to match up later on. For now, I have to figure the EIFS projection out protruding through the ceiling.

All I really have left is a few edits and I can wrap up Architectural by mid-week and begin MEP. I am shooting to have the model completed by the end of the week, with a few touch-ups continuing through Takeoff.

My main trouble was getting the EIFS/roof for the stairs working correctly. I had to go back to my structural to check a few slopes and adjust a few beams to make it work. It's still not as perfect as I need it to be, and I'm sure I'll be back in it to adjust the edges to match up later on. For now, I have to figure the EIFS projection out protruding through the ceiling.

All I really have left is a few edits and I can wrap up Architectural by mid-week and begin MEP. I am shooting to have the model completed by the end of the week, with a few touch-ups continuing through Takeoff.

Wednesday, September 15, 2010

Architectural

The architectural is coming along without too many problems. Placement of doors and windows is tricky with the double wall in placement, and I am having to edit the exterior brick veneer to compensate.

The stairwell brick was tricky but I was able to make it work. With a roof on and most elements in place, the architectural should be finished by the weekend. Even after completion I may go back during takeoff to edit/alter a few of my elements.

The stairwell brick was tricky but I was able to make it work. With a roof on and most elements in place, the architectural should be finished by the weekend. Even after completion I may go back during takeoff to edit/alter a few of my elements.

Sunday, September 12, 2010

Beginning Architectural

With the Structure complete, the hardest part seems to be over with for the moment. Though I expect a few complications along the way with the MEP and Arch, I don't feel I will have nearly as many problems as I did before with dimension conflict and placement.

Instead of just opening the Structural model in Architectural, I have used Revit's "Link Model" feature to import my Structure in as a single mass and build around it. The only downside seems to be that if something is out of place in the Structural, I will have to back out, re-open it, and then reload it into the model. However, this will help in insuring the takeoff is more accurate and things are where they need to be.

Instead of just opening the Structural model in Architectural, I have used Revit's "Link Model" feature to import my Structure in as a single mass and build around it. The only downside seems to be that if something is out of place in the Structural, I will have to back out, re-open it, and then reload it into the model. However, this will help in insuring the takeoff is more accurate and things are where they need to be.

Wednesday, September 8, 2010

Finishing Structure

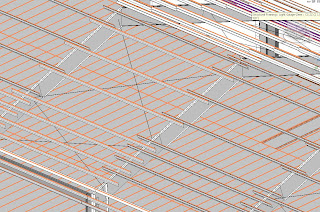

The roof joists gave me a world of trouble. Lack of spacing dimensions and dimensions in general has thrown me for a loop. I was able to throw it together eventually, with something I feel is as close as I can get to the actual building. Though not a perfect adaptation, it will have to do, as I must move on to the architectural model by tomorrow.

In closing out the structure I am finishing up stairs and railings. Instead of creating an additional landing at the top as I had predicted, I placed a slab on the second floor to act as the top landing and mirrored the stairs over. Placement is getting tricky as my slab dimensions are coming into question. I will have to reanalyze my dimensions on last time to insure a smooth transition to architectural.

I was also able to create a sweep for the cables. I will place these in the major areas along the grid lines and edges as shown.

Friday, September 3, 2010

Joists and Girder Placement

After a few measures to ensure column placement would adhere to the architectural alright, I decided to begin framing up the joists. Placement seems to be going smooth thus far, with the biggest trouble being an opening in the framing. I am filling in the "basics" for now, but should have a more detailed picture of connections if time allows.

Wednesday, September 1, 2010

Portal Frame and Fndn Check

With most of the foundation completed I am now throwing in steel. The Portal Frame is becoming a bit complicated, as I attempted to port in a family with multiple errors. I'm finding that Modeling in Place is the most useful tool to use in Revit. Though the Family Editor prepared me to use it effectively.

Tuesday, August 31, 2010

Finishing Foundation/Structure

I've made quite a bit of progress on the Foundation. I was able to complete the turn-down slab early this morning along with the continuous footings. I will have to join most of the geometry together once I ensure that everything is in place.

For the moment, I will finish up any Foundation work required such as the CMU wall I have near the stairs. A large majority of my foundation was created with "mass-in-place", which will require me to go back upon completion to ensure everything is labeled and detailed accordingly. I am unsure how it will affect my QTO later on, but I am trying to prepare for the issue preemptively.

For the moment, I will finish up any Foundation work required such as the CMU wall I have near the stairs. A large majority of my foundation was created with "mass-in-place", which will require me to go back upon completion to ensure everything is labeled and detailed accordingly. I am unsure how it will affect my QTO later on, but I am trying to prepare for the issue preemptively.

Monday, August 30, 2010

CAD Files/Foundation

I finally received the CAD files for the project, which will help me out a great deal. Though I do not have it for the joists, just ensuring my foundation is in the correct place was nice. I had to move a few things around but finally have it in place.

I plan to finish the Foundation of the project by Tuesday, and the rest of the structural by Friday. If I can finish this up, I should be able to fly through the Architectural.

My main problem, is that the structure of the PEMB means there are no other real load bearing walls. I have a few columns in the interior to mess with, but a lack of structural walls means complications in establishing a continuous footing. I'll have to research how to go about that today.

I plan to finish the Foundation of the project by Tuesday, and the rest of the structural by Friday. If I can finish this up, I should be able to fly through the Architectural.

My main problem, is that the structure of the PEMB means there are no other real load bearing walls. I have a few columns in the interior to mess with, but a lack of structural walls means complications in establishing a continuous footing. I'll have to research how to go about that today.

UPDATE:

I was finally able to import the CAD files successfully. It was a good thing too as my footings were off a few inches. Those will help a ton in throwing together the architectural plans and MEP. For now, they act as a great guide.

I finished the sloped slab for the stairs and began work on the footing turn down edge. It is incredibly tricky with the given dimensions for the corner. I was able to edit together a profile for the exterior walls in between column placement. The varying dimensions per column is proving the most difficult thing to adapt, as I must create a Mass-in-Place for those instances.

I should have turn down slab completed by at least tomorrow, leaving the footings as my next big challenge.

Friday, August 27, 2010

Finishing PEMB

Yesterday and today will be the last days I spend most of my time on this thing. Without proper dimensions labeled it is proving difficult to match the structure exactly. I scaled off the wall size of the architectural to check and ensure the structure itself will fit.

The connections and details aren't exactly precise, but I cannot spend anymore time concentrating on it. Though a few parameters work, I will see if I can split the family into sub-groups corresponding to each grid line. Finishing this up will speed things along as I continue on to the foundation.

The connections and details aren't exactly precise, but I cannot spend anymore time concentrating on it. Though a few parameters work, I will see if I can split the family into sub-groups corresponding to each grid line. Finishing this up will speed things along as I continue on to the foundation.

Wednesday, August 25, 2010

PEMB

Still struggling to get through this PEMB. Constructing it is proving difficult, especially with the plans given. Connections, but mostly dimensions, prove to be the most challenging in deciphering. I may end up having to get a "best I can do" structure thrown together.

The occasional breather was taken from the family editor to add in more columns/edits to the foundation itself. Hopefully I will be able to find a way to edit this to the best of my ability and move on to the foundation walls/slab. This is cutting into my time manipulating the model, what I want the focus of my thesis to become.

The occasional breather was taken from the family editor to add in more columns/edits to the foundation itself. Hopefully I will be able to find a way to edit this to the best of my ability and move on to the foundation walls/slab. This is cutting into my time manipulating the model, what I want the focus of my thesis to become.

Aug 18th - Aug 24th

Since this is my first post in the blog, I will mainly be using it as an introduction to what has been happening for the past week. I will be updating regularly from now on as a guide for both myself and future students in this Thesis.

I have begun my thesis by first laying out the grid lines and establishing isolated footing families. I had to customize a few families to suit the criteria that the plans dictated. Elevations have also been set. I have been using the 'Getting Started' help option as a sort of guide in what order I need to complete each event.

Unfortunately the first task of putting the structure up is proving the most difficult, as I have a pre-engineered metal building. These include tapered columns and members not typically found by default Google library searches. Using Revit City.com I have been able to procure something close to what I need.

I'm finding that I need to utilize the Family Editor to create the exact element I will need. I'm basically teaching myself at this point in creating and putting the members in place. Though I have been successful in creating the column and establishing parameters, there are still a few hitches I have yet to work out like creating the diagonal top. Not to mention the dimensions given vary for each part and I am having difficulty deciphering plans and getting exact dimensions.

Hopefully I will be finished with the actualy pre-engineered metal building by tomorrow and the actual structure itself over the weekend. I have a feeling this will be the most difficult part of the thesis, so tackling this quickly will prove helpful at later stages of thesis of giving myself more time.

I have begun my thesis by first laying out the grid lines and establishing isolated footing families. I had to customize a few families to suit the criteria that the plans dictated. Elevations have also been set. I have been using the 'Getting Started' help option as a sort of guide in what order I need to complete each event.

Unfortunately the first task of putting the structure up is proving the most difficult, as I have a pre-engineered metal building. These include tapered columns and members not typically found by default Google library searches. Using Revit City.com I have been able to procure something close to what I need.

Hopefully I will be finished with the actualy pre-engineered metal building by tomorrow and the actual structure itself over the weekend. I have a feeling this will be the most difficult part of the thesis, so tackling this quickly will prove helpful at later stages of thesis of giving myself more time.

Subscribe to:

Comments (Atom)